Why the oil and gas industry needs VR training

Working on oil rigs, using heavy equipment, exposure to hazardous chemicals, working at heights and enduring adverse weather conditions, oil and gas employees are no strangers to safety hazards. The oil and gas industry is the most dangerous industry to work in and has the highest death rate of any industry, with 489 oil and gas extraction workers experiencing loss of life between 2013 and 2017. This number should be much lower, in an ideal world, zero.

The goal is for employers to create the safest workplace possible to prevent hazards and fatalities from occurring. Creating a culture of workplace safety amongst employees that is embedded across the organisation’s culture is key. Prevention is better than cure and a strong health and safety culture begins with high-quality onboarding and training.

Traditional learning methods don’t tend well to safety training, resulting in check-box situations where employees read learning material and don’t retain any of their knowledge. 90% of employees find traditional training boring, and unrelated to their day-to-day job roles.

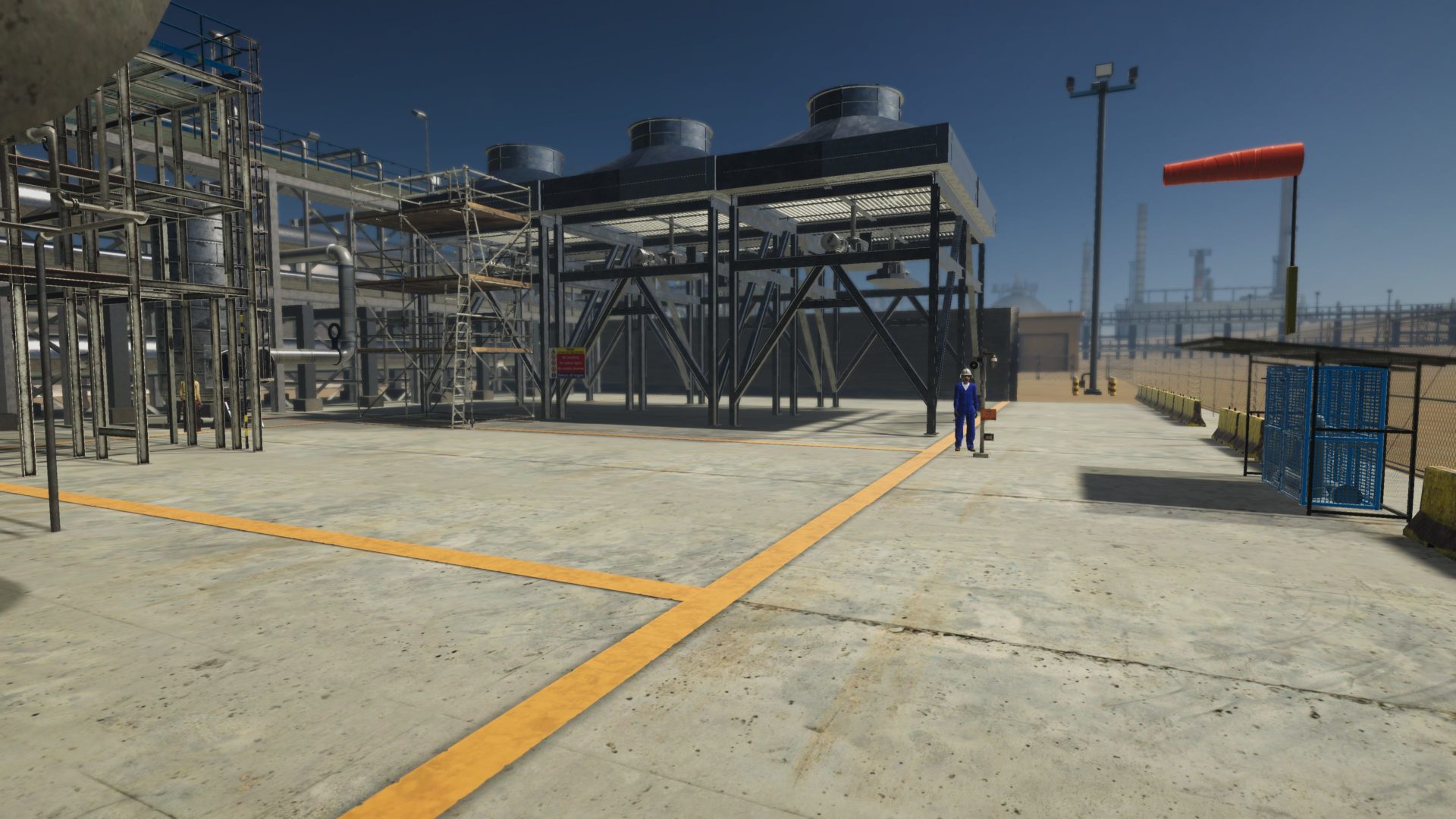

VR is the perfect solution for health and safety training, as VR training transports employees to the exact scenarios they’ll be encountering, enabling them to master tasks safely and repeatably. Bespoke VR content allows workers to experience situations as close to the real thing as possible.

The benefits are profound. Employees will feel valued and confident knowing they’re getting robust training and take their knowledge with them into the field, which will result in operational efficiency.

In this blog, we’ll take you through:

· What is VR training and how does it work in the oil and gas sector

· How VR is transforming the oil and gas industry

· Use cases of VR training for oil and gas

· The benefits of VR training

What is VR training and how does it work in the oil and gas sector?

VR training is where a person enters a virtual environment using a VR headset or desktop computer where they can practice skills repeatably, memorising and retaining their knowledge. VR training is especially useful for employees in the oil and gas sector because it enables them to perfect important procedures in their day-to-day roles.

Training in VR is the best learning method as it eliminates the danger of practicing on live machinery and gives the trainee first-hand experience that they wouldn’t get from shadowing an expert.

How is VR transforming the oil and gas industry?

Virtual reality training is having a profound effect on businesses through employee training and development, let’s take a look…

1) VR is solving Operational Challenges

Picture this, you’re a global business with multiple sites and employees dispersed geographically. How do you effectively train each and every employee to the same, high-quality standard?

You could host on-site training over a few days, but this results in paying for each employee to travel to the site, accommodation costs, the time and resource needed for trainers, a potential plant shut down which can incur huge costs. The logistics of getting everyone together to train can be incredibly costly and difficult.

By combining the use of digital twins and virtual reality training, you can create an interactive replica of your work environment in the metaverse. Whether it’s a virtual oil rig, a petroleum storage tank, reserve pits or drilling platforms your staff can interact with the environment and 3D versions of your equipment safely, from anywhere in the world through a VR headset.

The cost savings are incredible with training in remote environments saving as much as $50 billion per year for unplanned down time.

2) VR is addressing Skills Shortages

The CIPD found that some of the most important learning and development priorities are:

· Addressing skills gaps

· Improving inductions and onboarding

· Identifying changing skills requirements

With older crew making up nearly 50% of industry personnel, and many of them retiring in the next five to seven years, the result is a heavily shrinking pool of specialists and knowledge loss across the sector which will have a far-reaching impact.

VR training plays a huge part here. By working with current employees to understand their knowledge, skills and experiences, VR oil and gas scenarios can be created that allow trainees to practice these specific skills and benefit from their knowledge, anytime and anywhere.

3) VR is improving Health & Safety

As the industry with the highest fatality rate, health and safety is the most important issue for employers in the oil and gas industry. Safety incidents can have a huge ripple effect on employee wellbeing, productivity as well as fines and reputational damage for businesses.

A well-trained team is the make or break for preventing hazards and fatalities. By investing in high quality, bespoke VR safety training that replicates your employee’s day to day practices your teams will be physically, confidently prepared for tasks.

VR training means you can always stay ahead of the curve with rules and regulations, updating safety training as necessary and keeping updated on the latest safety regulations. Bespoke virtual reality can be created so employees can train for a range of hazards they’ll encounter in the workplace, improving confidence and enabling them to deal with situations correctly, preventing hazards and accidents. Let’s look at some of the most common hazards in the oil and gas industry that can be recreated in VR.

The Most Common Oil & Gas Workplace Hazards

Chemical Hazards

Chemicals pose a huge risk to workers’ health and safety. From corrosive substances to toxic gases, exposure can lead to severe health complications which is why appropriate action and training such as wearing the correct PPE and effective engineering controls are so important.

Welding

Welding, whilst an essential task for construction and repair in oil and gas, brings its own set of hazards. From intense heat to toxic fumes, welders brave a whole host of risks, meaning attention to safety protocols to avert accidents and injuries is paramount.

Confined Spaces

Whether it’s work in a storage tank, pit, wellhead, or tunnels working in confined spaces can be very dangerous. With limited ventilation and potential exposure to toxic gases, navigating confined spaces can be a huge risk for employees.

Falls

Falls are a significant danger in the oil and gas industry, with 42,000 workers injured by falls annually. 30% of falls are caused by working at heights. Whether working atop rigs or navigating slippery surfaces, the risk of falls looms large, highlighting the importance of safety procedures.

Machine Hazards

From drilling rigs to heavy equipment, machines can bring the potential for catastrophe if mishandled. Diligent maintenance, comprehensive training, and strict adherence to safety protocols are crucial to mitigate the risks and injuries.

Explosions & Fires

Fires can occur when flammable liquids or vapours are exposed to things like lightning, cigarettes, open flames, sparks from hot work and even sources like static, friction, and hot surfaces. Explosions occur when fires become out of control or when vessels break under pressure.

The quality of your employees training programmes have a huge impact on the outcome of their day to day work. In fact, A YouGov survey of more than 2,000 frontline workers in Australia, the US and the UK found that 64% of respondents believe better training can prevent at least a few of the injuries that they had witnessed or experienced first hand.

Investing in bespoke, high quality virtual training content that replicates your standard operation procedures for specific tasks is a great way of training employees, giving them that first hand experience and allowing them to build muscle memory.

Our off-the-shelf VR Safety Skills module allows you to implement training on PPE and Work Permits, Confined Spaces, Working at Heights, Hot Work and Line and Equipment opening straight away.

VR Use Cases in Oil & Gas Safety Training

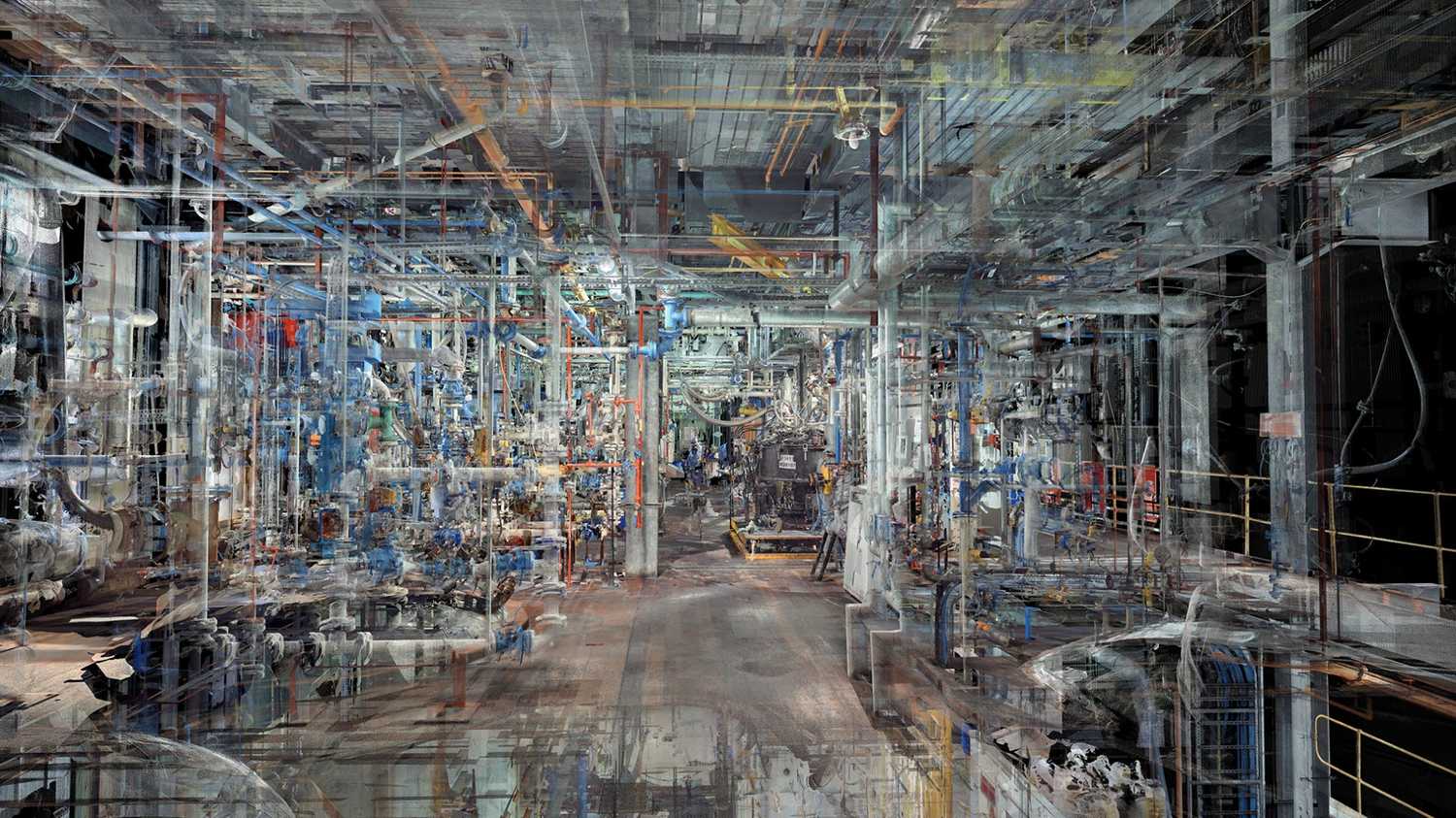

VR aids training by creating a completely virtual, risk free environment for employees to train in. 3D Scanning can be used to create a digital twin of your work environment and 3D Modelling can be used to replicate your specific equipment virtually. VR is then used to create bespoke training scenarios suited to your employee’s job roles. Let’s look at VR use cases in more detail:

Immersive Training

Equipment & Machinery Operation Training in VR

Operating heavy machinery and equipment demands precision and expertise. VR simulations offer a safe space for employees to familiarize themselves with complex machinery, practice operational procedures, and troubleshoot common issues without risking real-world accidents.

Emergency Response & Evacuation Drills in VR

In emergency situations, quick and effective response can save lives. VR training facilitates realistic emergency scenarios, allowing trainees to simulate response protocols, practice evacuation procedures, and make split-second decisions under pressure. This immersive training enhances preparedness and fosters a culture of safety.

Hazard Recognition & Risk Assessment in VR

Virtual reality simulations can vividly recreate various scenarios, allowing trainees to identify potential hazards and risks in a controlled environment. From recognizing chemical leaks to spotting faulty equipment, VR immerses trainees in lifelike situations, honing their ability to detect dangers effectively.

Why not check our our off-the-shelf Hazard Recognition course?

Digital Twins

Digital twins revolutionize safety training by creating virtual replicas of real-world assets, environments, and processes. Here’s how they contribute to enhancing safety in the oil and gas industry:

Realistic Environment Simulation

Digital twins can be used to create virtual versions of your infrastructure – oil rigs, refineries, pipelines and more. Trainees can explore these virtual environments, interact with equipment, and familiarize themselves with operational workflows, enhancing their understanding of workplace dynamics.

Predictive Maintenance Training

Trainees can learn predictive maintenance techniques through virtual equipment performance to identify early warning signs, schedule maintenance tasks proactively, and optimize asset reliability, thereby reducing the risk of unplanned downtime and accidents.

The benefits of immersive learning for businesses is incredible, giving employees the ability to perfect and become confident in their abilities in the workplace. But where do you begin with getting VR training implemented across the business?

How to develop and implement a VR safety training solution programme

Implementing a VR safety training solution requires careful planning, collaboration, and technological expertise. There are three key steps to implementing VR within your business:

1) An Envisioning Workshop: Envisioning workshops are the perfect place to start when educating everyone in the business around VR. They’re dedicated brainstorming sessions involving key stakeholders to discuss important questions, define goals for VR training and create a roadmap for implementation.

2) A Strategized Pilot Project: Once the right VR training scenario has been decided it must then be created for the pilot project where two groups are assessed, one group with traditional learning methods, the other use bespoke VR training.

3) The Official VR Training Roll Out: From the results of the pilot project, you can present the case to leadership, secure funding, establish the ecosystem for successful implementation and plan more training scenarios, with ongoing support at every stage.

Want to get started with a VR training pilot project? We run dedicated and specialised XR Envisioning Session to help you get started with your pilot project to help you prove the ROI of VR training.